Claitec Safety Solutions

FillisLift is the official partner of Claitec in Greece.

Claitec is a technology-driven company specialising in the implementation of industrial safety and accident prevention solutions. Their product range consists of several safety systems that can be customised to suit the needs of each company. Through the years, Claitec has developed a comprehensive range of solutions aimed at minimising occupational hazards in industrial environments with high risk of accidents. Their systems improve safety levels and provide forklift operators increased protection, always ensuring a safe and controlled workplace.

Let’s take a closer look at their products!

Pedestrian Alert System (PAS)

What Is It?

The Pedestrian Alert System (PAS) is a solution designed to warn forklift drivers when detecting a person at adjustable distances of 1 to 6.5 meters. It is a unique system with the capacity to discriminate between people and objects. It even detects operators who are behind a wall or a shelf!

How Does It Work?

Pedestrians carry Tags (Electronic keyfobs). When these are detected by the system previously installed in forklifts, it alerts the driver with warning light signals. This way the warned driver is aware that there is a person near his/her work area and can then take the necessary precautions.

Where Can It Be Used?

The Pedestrian Alert System is ideal for use in loading and unloading areas in industries and factory spaces. It is also ideal for use in areas with poor visibility where pedestrians interact with forklifts and warehouse aisle exits. In general, it is a highly recommended system for spaces or work areas shared between forklifts and pedestrians - such as production lines -, where the space for pedestrian and forklift traffic is very limited, and where it is essential to take extreme measures care and caution measures.

Advantages:

The system increases accident prevention levels in high-risk areas. In addition, it provides greater care for both operators and external persons who are touring the facilities. Having this type of system will also allow you to negotiate better insurance policies and achieve a reduction in the instalments to be paid. In addition, there’s another aspect of this system that differentiates from other options in the market: it is capable of discriminating between obstacles and people, thus being a lot more efficient.

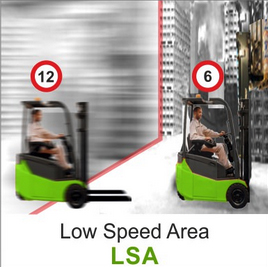

Low Speed Area (LSA)

What Is It?

The main objective of the LSA Solution is to limit the speed at which forklifts circulate. This electronic safety system is specially designed to complement forklifts’ safety tools and to reduce their speed in areas where there are operators on foot or pedestrians.

How Does It Work?

Once the system is installed, its operation is very simple, and it requires no action from the operator. The truck that is equipped with the LSA Solution reacts upon entering an area in which the use of the system was predetermined, activating a signal that compels it to adapt to the established limit in the "slow" or "fast" zones.

Where Can It Be Used?

This solution is specially designed for warehouses, loading and unloading docks, industries or workspaces, although it can be perfectly adapted to different work sites that required special attention. In that sense and as our clients have been proving, the possibilities are very broad.

Advantages:

Besides its very easy installation, the LSA Solution stands out for being highly practical and for generating a very large contribution in terms of accident reduction, decrease in accidents and general improvement of the safety conditions in all industries.

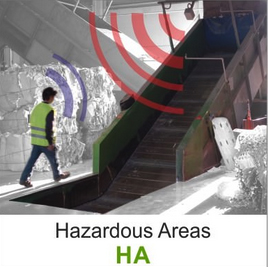

Hazardous Areas (HA)

What Is It?

The HA Solution automatically stops a machine – a crusher, for instance - when a person with the corresponding tag approaches the area indicated as "danger zone", or when a person falls inside a conveyor belt perhaps as a result of being knocked off, fainting or similar situations. This system generates a safe protocol which establishes that upon a person’s entry all activity will cease thus avoiding accidents or damages.

How Does It Work?

The system is responsible for detecting when a safety tag – carried by the operator as a personal key ring - enters the area configured as a "danger zone". In that case it immediately stops the machine installed there and specially configured under this solution. The interaction between the staff’s key ring and the antenna installed - whether in a crusher, compactor or any other similar machine - is generated automatically without the need for permanent human control. It provides greater safety in areas that are traditionally high occupational accident-prone zones. The system also records the date and time the machine stopped, as well as the tag number detected in the risk zone, in order to apply safety policies in this regard and avoid similar situations in the future. In addition, this solution provides the possibility of verifying that the system is operative as an indispensable condition to work safely within the perimeter of the machine.

Where Can It Be Used?

The HA system is specially designed to be used in areas surrounding pits, presses, crushers or compactors, among other highly dangerous tools. It is also frequently used in areas located next to large conveyor belts.

Advantages:

• The HA system stands out for the durability and robustness of the devices that compose it.

• The different elements are not affected by the vibration of the motors, they are not affected by interferences between antennas nor by the metal structures of the machines.

• The keychain is detected in any position even when covered with material.

• The quality of the system prevents false alarms from being generated, due to the regular adjustment of the antennas.

• It also stands out for its ease of installation, and for the possibility of acquiring it through "turnkey projects" by Claitec or your local installer.

Truck Docking System (TDS)

What Is It?

The traffic light of the Truck Loading and Unloading Safety (TDS) cautions the driver of the presence of other personnel at a loading dock.

How Does It Work?

The dock is equipped with detection sensors which, after detecting a person, issue a signal to the traffic light. Upon being alerted by the traffic light, they can apply extreme caution and attempt to load or unload the goods carried on the dock without any risks.

Where Can It Be Used?

Loading and unloading docks.

Advantages:

• Detection of personnel in loading docks.

• Easy installation by dealer.

• Durable and robust system components.

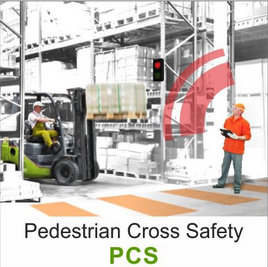

Pedestrian Crossing Safety (PCS):

What Is It?

The Pedestrian Crossing Safety (PCS) solution is a system of traffic lights that indicates the presence of pedestrians crossing to forklift drivers.

How Does It Work?

Pedestrians are fitted with a series of tags or transponders which, emit light signals that are detected by an activator. Subsequently, the lights indicate the presence of pedestrians in the vicinity.

Where Can It Be Used?

• Loading and unloading zones.

• Poor visibility areas at junctions between pedestrians and forklifts.

• Areas with high forklift traffic.

Advantages:

• Detection of trucks in the proximity of the traffic light.

• Easy installation.

• Durable and robust system components.

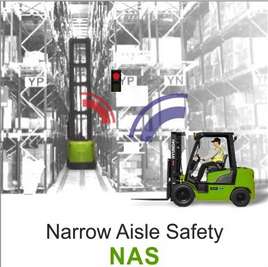

Narrow Aisle Safety (NAS)

What Is It?

The traffic light featured by the Narrow Aisle Safety (NAS) solution cautions forklift drivers of the proximity of another forklift in areas with limited room to manoeuvre.

How Does It Work?

The forklifts incorporate reflective coded bands that when there are detected by the code detection sensors activates the traffic lights installed in this aisle. The forklifts incorporate reflective codeds bands that when there are detected by the code detection sensors activates the traffic lights installed in this aisle. From that moment, and while the forklift is in the aisle, the traffic light will indicate its presence in the area for the rest of the vehicles or pedestrians that approach the place.

Where Can It Be Used?

• Confined areas.

• Poor visibility areas at junctions between forklifts.

• Areas with high forklift traffic.

Advantages:

• Detection of trucks in the proximity of the traffic light and adjacent corridors.

• Easy installation.

• Durable and robust system components.

• Flexible and scalable, it fits most applications.

Blind Spots (BS)

What Is It?

The Blind Spots (BS) solution is a system of traffic lights designed to indicate the right of way of drivers and pedestrians.

How Does It Work?

Both pedestrians and forklifts are fitted with a series of tags or transponders which, emit light signals that are detected by a traffic light. Upon detection, the traffic light indicates who has the right of way.

Where Can It Be Used?

• Loading and unloading zones.

• Poor visibility areas at junctions between pedestrians and forklifts.

• Areas with high forklift traffic.

Advantages:

• Detection of trucks in the proximity of the traffic light.

• Easy installation.

• Durable and robust system components.

Collision Avoidance System (CAS-G2)

What Is It?

The CAS-G2 is designed to reduce work accidents caused by collisions among cargo vehicles. As a support system for drivers it provides more information about the space through which they circulate. It allows the person manoeuvring the vehicle to learn about the position of other forklifts and bring them into the equation when making driving decisions. The CAS-G2 is a system which compliments other tools designed to enhance safety at work.

How Does It Work?

Once a forklift is equipped with the CAS-G2 system, it will detect other vehicles also fitted with the same device. The detection zones are configurable, with a range of up to 40 meters. This means that even if a forklift is travelling through a blind spot or moving behind a shelf or a space that prevents it from being clearly seen, the system will detect its presence and warn drivers approaching so that they can take the necessary precautions.

Where Can It Be Used?

The CAS-G2 system can be used in loading and unloading areas, spaces with low visibility, places with pedestrian and forklift crossings, workspaces where pedestrians and load vehicles coincide and spaces with high intensity forklift traffic. It is ideal for warehouses, ports, factories and industries.

Advantages:

This CAS-G2 system stands out for the many advantages it offers any of the sectors mentioned above. Among other things:

• It has proven to reduce accidents in areas with high volume of forklift traffic.

• It’s easily implemented.

• It can be used in all types of industrial vehicles.

• It’s durable and built with robust components.

Fall Protection System (FPS)

What Is It?

This is a retractable safety device which, is anchored to a fixed element and connected to the worker with a safety harness. When a fall occurs, the harness tenses up and the Fall Protection Device detects this tension. This device is also responsible for sending the stop signal to the machinery in the plant, causing a quick halt in the functioning of the machine.

How Does It Work?

The device must be connected to the fixed mooring point, by means of the bearing swivel and the connector. Naturally, the fixed clamping point must be located above the user, in order for the force of gravity of the fall itself to cause the desired effect of generating the sudden tension in the harness. In addition, the connection must have a minimum static resistance of 12kN. The shape and structure of the fixed clamping point should be sufficient to prevent the device’s automatic disconnection and slippage. The use of fixed mooring points marked and certified is recommended, according to the European standard EN795.

Where Can It Be Used?

• Presses and crushers, compactors.

• Edge detection in pits.

Advantages:

• Machine stops when detecting a fall of a worker.

• Easy to install.

• Durable and robust system components.

• Avoid false alarms.

• Capacity of utilization in all kinds of hazardous areas.

Traffic Control System (TCS)

What Is It?

The TCS solution is designed to prevent accidents between people and cargo vehicles. Forklift circulating around the workspace automatically activate the warning and signalling elements previously installed at different points in this space. The system provides an automated control in the spaces shared by operators and forklifts.

How Does It Work?

The forklifts incorporate a PAS system with an AC-50 activator that generates a radio frequency field around it.

Similarly, TZ2-Tag devices are installed in different points of the workspace to detect previously equipped vehicles.

When a forklift enters the safety zone defined by the TZ2-Tag, the vehicle and warehouse lighting warnings are activated, alerting those in the vicinity of the presence of the vehicle.

At the same time, the system automatically turns the pedestrian traffic light red and blocks the safety gate to prevent any pedestrians from crossing. Only when the vehicle leaves the safety space, the traffic light will turn green and the gates will open.

Where Can It Be Used?

The Traffic Control System is ideal to be used in work areas with little or no visibility, in spaces with a lot of forklift and operator traffic, and sites with pedestrian-forklift crossings. For example, it is frequently installed in factory spaces, warehouses, loading docks, production lines and other industrial sites.

Advantages:

• This system is especially outstanding for its effectiveness and ability to solve problems. In spaces where accident at work rates are high, the TCS Solution provides security and it eradicates human error in relation to such important matters as accident prevention alerts and actions.

• The automation of the signals and pedestrian/forklifts segregation mechanisms becomes of great assistance and its results are very easily verifiable.

• You can install as many tags in parallel as necessary. This allows you to expand the alert zone and configure it according to the interests of each client and the needs of each workspace.

Visual Alert System (VAS)

What Is It?

The Safety Alert Visualisation solution is an innovative development which warns pedestrians and/or forklifts in situations of risk by projecting signals on the ground.

How Does It Work?

The projector has 1 to 3 different colour lenses and the projected symbols are customisable. Some examples of what can be projected are a forklift sign, pedestrian signs, a STOP warning, a pedestrian crossing, a speed limit sign, a “no smoking” sign warning or a signal indicating that the use of mobile phones is prohibited, among many other options.

Where Can It Be Used?

This system is ideal for use in warehouses, logistics centres, production areas, spaces separating production areas from offices, corridors and transit areas in industrial spaces, as well as in blind spots in workspaces.

Advantages:

This system differs from other signage options in that its highly effective and visible. Experience shows us that projections on the ground provide better visibility than those projected above. They are also better than the commonly used panoramic mirrors, since these are often placed too high to be seen and paid attention to. In many cases, these mirrors become part of the landscape of the workspace and operators don’t give them due consideration. On the other hand, with a projector that emits a signal on the ground it’s easier to capture a person’s attention. This person receives a much more direct and easier to detect warning, is more protected and can circulate safely. In a nutshell, there are many benefits to the VAS system: the image is easy to see, it doesn’t wear out, it can be turned on and off, the projected signs can be changed, the marks are very visible, and they attract a lot of attention.

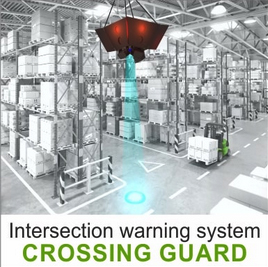

Crossing Guard

What Is It?

This system is used to prevent collisions or similar work accidents at the intersections of warehouses or industrial spaces. It protects forklift operators and drivers in these areas, which frequently record safety incidents.

How Does It Work?

When the vehicle or person approaches the intersection area it receives a visual alert from the traffic lights and the projection via the Bluespot or the VAS projector indicating whether or not he or she has permission to cross the intersection. The Crossing Guard system uses radar technology capable of differentiating persons from vehicles and identifying whether a forklift is approaching an intersection or if it is moving away from it.

Where Can It Be Used?

The Crossing Guard has been specifically developed to be used in warehouses, loading docks or industrial spaces with hazardous intersections, and where operators and loading machinery tend to converge.

Advantages:

• Its robust aluminium structure.

• The possibility of operating at a mounting height of 2 to 7 meters.

• Its extremely easy handling even at a height.

• A vehicle detection speed of a maximum 25 km/h.

Similarly, with this innovative technology, it is no longer necessary for operators or vehicles to carry a device to be detected since the system locates them on its own.

In addition, it is important to highlight that the separation fins in this device ensure other traffic lights are not seen from the same angle to avoid confusion.